Find Your Backshell

All our backshells are compatible with a wide range of Mil-Spec and commercial connectors for uncompromised EMI/RFI protection.

Find Backshells by MIL-Spec

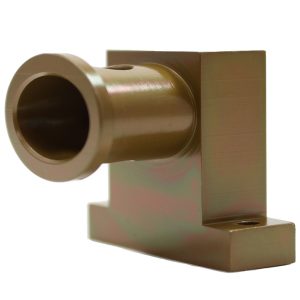

Isodyne’s Tool-less EMI/RFI Backshell System

Isodyne’s connector backshell Tool-less Braid Termination System was specifically designed to provide better mechanical and electrical performance for wire harnesses requiring shielding protection for EMI/RFI, HIRF and lightning. Both the individual shields and the overbraid are terminated at the backshell with one band. Our spring band can be installed and removed thousands of times with no tools allowing for easy re-entry of the cable assembly for repair or re-pinning and no degradation of spring force. The Isodyne backshell system has been in use since 1990 on land, sea, air and space platforms requiring a higher performance connector backshell.

For Quotes or Questions Call – 316-682-5634The Isodyne Tool-less Braid Termination Systems also provides numerous benefits in the communications fields supporting applications in radios, Satcom, UAV market, military fixed and rotary wing aircraft. The Isodyne Tool-less Braid Termination system is widely recognized for consistently high quality and superior performance. |

The Isodyne connector system is made up of an EMI backshell with a spring banding area populated with slots to allow the individual drain wires direct contact with the backshell body. The Isodyne system allows for assembly and disassembly of the over braid to the backshell without the need for a tool.

|