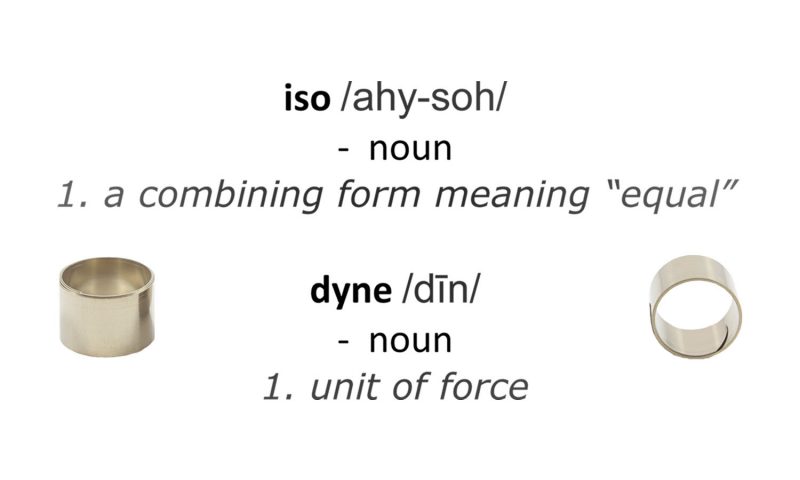

Isodyne develops and manufactures a patented Tool-Less Braid Termination System for EMI back shells specifically designed for wire harnesses requiring shielding for EMI/RFI or HERF and lightning protection. Both individual shields and overbraid are terminated at the backshell with one band improving electrical performance also allowing for ease of re-entry.

The band can be removed and replaced allowing for easy repair/upgrade of the system without the need for calibrated tools.

This design has been in use since 1990 and is in use thousands of interconnects on land-based systems such as the M1/A2 tank. Because of the conforce springs inherent memory in high shock and vibration applications the spring tightens increasing reliability. For these reasons Isodyne EMI backshells are on most military helicopters, C130, KC-135 tanker and Unmanned Vehicles.

Our Tool-less Braid Termination Systems also excels in the communications fields with applications in everything from radios to antennas for the wireless market. The Isodyne Tool-less Braid Termination system is widely recognized for its ease of use, mechanical benefits and superior EMI performance.

History

In May of 1995, Isodyne began doing business as a small company dedicated to superior customer service and quality. These founding principles, coupled with constant innovation, are what have led Isodyne to what it is today. We take great pride in presenting the proper solution to each of our customers and doing so in a timely manner. Today we offer custom solutions and design services along with our standard products; all while maintaining that dedication to the customer.

– Lynn Reed, President, CEO, Founding Partner