Reliability & Performance

The Isodyne Difference

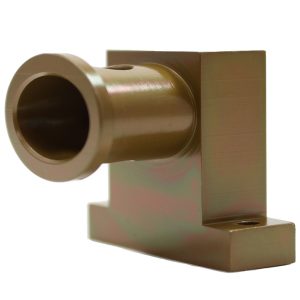

When reliability and performance are critical, Isodyne’s backshells surpass industry standards, ensuring your connections are secure and your signal integrity is flawless. Our innovative Tool-less Braid Termination System provides aerospace engineers and manufacturers a seamless solution for re-pinning or repairing wire harnesses under the most demanding conditions.

Aerospace and military giants like Boeing, Raytheon, and Lockheed Martin rely on the unmatched mechanical and electrical performance of our connector backshells to ensure mission success in any environment.

The Isodyne Tool-less Braid Termination System stands out with key features such as:

No Tools Required: Our tool-less system makes assembly, removal, re-pinning or repair a breeze with no compromise in spring force, reducing your repair cycle time. No more calibration of crimp banding tools needed!

Enhanced EMI/RFI Performance: Our integrative design facilitates consistent and robust shielding protection for sensitive electronics.

No Solder Sleeves Needed: Our slots eliminate the need for solder sleeves.

Constant Force Spring Bands: Our constant force spring band can increase holding force and lowers resistance under vibration, improving EMI performance. The stainless steel spring band can be installed and removed thousands of times with no degradation of holding force.

Built for Harsh Environments: Tensile pull strength 125 ft/lbs almost doubling when a heat shrink boot is added. The reduced component count helps control FOD, lighter weight, and faster assembly time.

Widespread Industry Adaptability: From military to commercial to satellite communications, our systems cater to diverse applications, promising quality and reliability.

Find Your Backshell

All our backshells are compatible with a wide range of Mil-Spec and commercial connectors for uncompromised EMI/RFI protection.

Find Backshells by MIL-Spec

FAA Testing

AS85049 Connector Accessories

Isodyne products are designed and manufactured to satisfy the rigorous mechanical, environmental, and electrical requirements defined in the AS85049 standard. Our test report documents our compliance to meet or exceed AS85049 specifications, ensuring uncompromised performance and reliability for your application.

Test conducted to the AS85049 Standard

- Magnetic Permeability

- Shell Conductivity

- Shock / Vibration

- Corrosion – Salt Spray

- Cable Pull Out

- Coupling Thread Strength

- External Bend Moment

- Fluid Emersion

- Thermal Aging

Request the Report

UNRIVALED QUALITY

Uncompromising Performance

Isodyne is known in the industry as a leading backshell manufacturer and precision products. Our electrical connector backshells are engineered to deliver peace of mind by combining advanced technology with rigorous quality control measures. Isodyne’s commitment to exceeding customer expectations ensures:

Superior Material Strength: With a tensile pull strength of 125 ft/lbs, Isodyne backshells are built for the tough tasks.

Seamless Assembly and Disassembly: The Isodyne Tool-less Braid Termination System allows you to work efficiently, without the need for extra tools and specialized training.

Reduced Calibration Hassles: Simplifying your maintenance and repair workflows with an approach that’s designed for long-term performance.

Strain Relief Backshells: Isodyne offers a range of backshells that provide strain relief for high vibration applications.

Testimonials

Mission

Accomplished

Terminating cable shields to backshells using traditional methods is a time-consuming and expensive operation filled with opportunities for error. Isodyne makes a unique solution that reduces work and simplifies the entire assembly operation. Dynetics Cable Shop would like to see Isodyne backshells called out on our drawings in the future to take advantage of the backshell’s features and benefits.

Richard Wietlake - Senior Engineer, Dynetics

DISCOVER THE

Isodyne Advantage

Ready to upgrade your electrical systems? Our backshells are trusted by the industry’s leading innovators. Don’t just settle for a good connection—demand a great one that’s built to last and perform in the most extreme environments. Take the first step and browse our full range of backshells today. Use our intuitive filter system to find the perfect solution tailored to your specifications.

View All Backshells

Backshells for Military Aircraft

Backshells for Land Vehicles

Backshells for Navy & Sea

Backshells for Space & Satellites

Backshells for Defense Systems

Backshells for Radar Systems

Backshells for Communications

Backshells for Drones

Backshells for Rail

Backshells for Commercial Aircraft

Backshells for Private Aircraft