Custom EMI/RFI Backshell Solutions

Solving customer problems to what we do everyday at Isodyne. The combined experience of a trained sales team along with excellent sales support helps create solutions that meet design, cost and time line objectives. Not all solutions can be found in a catalog. Isodyne understands that the solution best suited to your application may not be found in print or on anyone else’s website. We have built a rich pedigree by meeting and exceeding our customer expectations. Isodyne leads the industry by working collaboratively with our customers to create efficient and effective custom solutions. From early design and defining the performance requirements to prototype to finished product, Isodyne is there. Land, sea, air, or space; no build is too large or too small. Please contact the factory with any requests.

Call us at – 316-682-5634

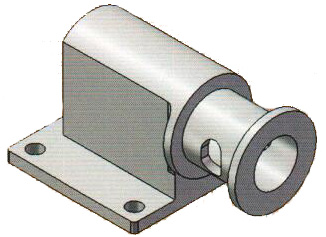

Custom configurations are common for the Isodyne team and we rise to the challenge every time. From a few parts for a satellite program to high volume requirements for land sea or air applications. This customer had already built their cables when they found out they needed EMI shielding. Cutting off the connectors was not an option so Isodyne developed the 206 series Split D-sub back shell. The sample in the picture incorporates the Integrated Strain Relief systems, also an Isodyne back shell improvement.

Custom configurations are common for the Isodyne team and we rise to the challenge every time. From a few parts for a satellite program to high volume requirements for land sea or air applications. This customer had already built their cables when they found out they needed EMI shielding. Cutting off the connectors was not an option so Isodyne developed the 206 series Split D-sub back shell. The sample in the picture incorporates the Integrated Strain Relief systems, also an Isodyne back shell improvement.

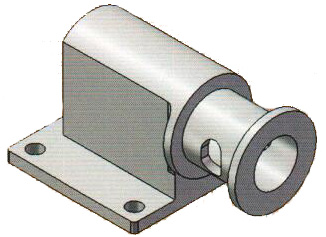

In-House Rapid Prototyping

Isodyne has the in-house capability to supply rapid prototype EMI backshells that provide form, fit, and feel early in your product development stages. We supply 3D STP files allow you to model the backshell in your application, and a plastic prototype easily confirms the data. This process can be done in a few days depending on machine time availability.

Isodyne has the in-house capability to supply rapid prototype EMI backshells that provide form, fit, and feel early in your product development stages. We supply 3D STP files allow you to model the backshell in your application, and a plastic prototype easily confirms the data. This process can be done in a few days depending on machine time availability.

Benefits of Rapid Prototyping EMI Backshells

- Faster development of your products

- Prototype produced in days instead of weeks

- Dimensionally accurate and durable samples

- Provide form, fit, and feel

- Typically no cost to customer

Custom Product Development

In addition to our in house SLA capabilities Isodyne now has limited in house machining capabilities to support custom product development allowing better control over lead times and set up cost. The ability to create the solution, provide an SLA sample in a few days and follow up with a machined part helps to streamline the process These added value services have helped many programs get back on track, creating value to our customers when they need us most.

In addition to our in house SLA capabilities Isodyne now has limited in house machining capabilities to support custom product development allowing better control over lead times and set up cost. The ability to create the solution, provide an SLA sample in a few days and follow up with a machined part helps to streamline the process These added value services have helped many programs get back on track, creating value to our customers when they need us most.

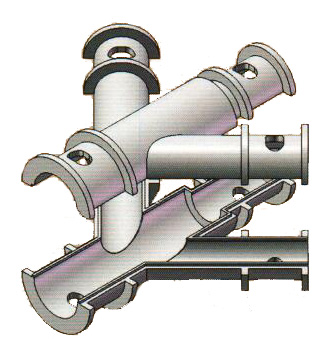

ARINC custom solution. User defined cable entries and Strain Relief. Hinged access to connector inserts.

Custom Spice Kit. User defined angles, cable entries, and diameters.

Custom Bulkhead Feed Through. User defined profile and dimensions.